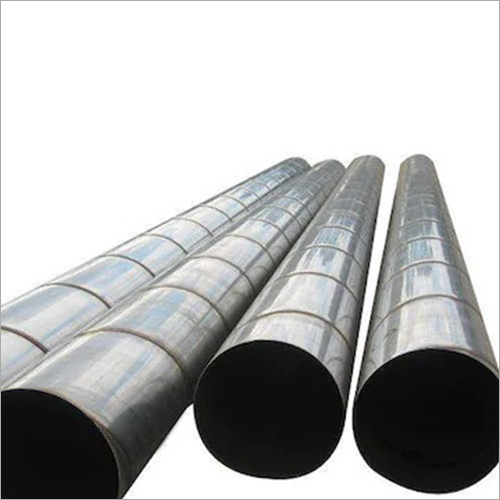

Spiral Welded Pipe

Product Details:

- Application Fluid Pipe, Construction

- Section Shape Round

- Feature Durable

- Material Mild Steel

- Product Type Mild Steel Pipes

- Type Galvanized

- Shape Round

- Click to View more

Spiral Welded Pipe Price And Quantity

- 1 Ton

- 98 INR/Kilograms

Spiral Welded Pipe Product Specifications

- Mild Steel

- Mild Steel Pipes

- Round

- Hot Rolled

- Durable

- Round

- Customized

- Galvanized

- Galvanized

- Fluid Pipe, Construction

- A Grade

Spiral Welded Pipe Trade Information

- Cash in Advance (CID)

- 100 Ton Per Month

- 2-5 Days

- All India

Product Description

Spiral Welded Pipe is other terms for spiral pipe. We use steel strip coil as the raw material, then extrude it at room temperature and weld using an automatic double wire double-sided submerged arc welding technique the outer diameter. The wall thickness defines the requirements of the pipe, which is utilized for oil and natural gas pipelines. The hydrostatic test of weld joints, tensile strength, and cold bending performance must all be in line with the regulations for the Spiral Welded Pipe.

FAQs of Spiral Welded Pipe:

Q: What is a spiral welded pipe?

A: A spiral welded pipe is a sort of steel pipe that is produced by spiral-welding steel strips or loops around a tube shaped structure to make a consistent spiral crease. This strategy for pipe fabricating gives strength, sturdiness, and the capacity to deliver pipes with bigger measurements.

Q: What kinds of steel are utilized for spiral welded pipes?

A: Spiral welded pipes are commonly produced using carbon steel or low-compound steel. The decision of steel grade relies upon the particular application and the expected strength and erosion opposition.

Q: Are spiral welded pipes appropriate for high-pressure applications?

A: Spiral welded pipes can be designed to endure high-pressure applications, like oil and gas pipelines, when they are planned and made to meet the expected determinations and norms. Factors like pipe width, wall thickness, and steel grade are basic in deciding the reasonableness for high-pressure use.

Q: Can spiral welded pipes be utilized for underground applications?

A: Indeed, spiral welded pipes can be utilized for underground applications, yet they ought to be covered or safeguarded to forestall consumption. Coatings, for example, combination reinforced epoxy (FBE) or polyethylene are frequently applied to safeguard the pipes when covered underground.

Q: Are spiral welded pipes appropriate for use in destructive conditions?

A: Spiral welded pipes can be covered or fixed with materials that upgrade their protection from consumption, making them appropriate for use in destructive conditions. Covering choices rely upon the particular destructive variables and the planned application.

Q: What are the support prerequisites for spiral welded pipes?

A: Upkeep prerequisites for spiral welded pipes normally include intermittent assessments for consumption, harm, or breaks. Appropriate coatings and cathodic assurance frameworks can assist with expanding the life expectancy of these pipes in destructive conditions. Ordinary upkeep practices and examinations ought to be followed to guarantee the pipes' respectability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+