ERW G.I.Pipe

Product Details:

- Section Shape Round

- Surface Finish Zinc coated

- End Protector Rubber Pipe Cap

- Type Galvanized

- Shape Round

- Technique Electric Resistance Welded (ERW)

- Click to View more

ERW G.I.Pipe Price and Quantity

- 70000.00 - 90000.00 INR/Ton

- 80000 INR/Ton

- 1 Ton

ERW G.I.Pipe Specification

- Electric Resistance Welded (ERW)

- Round

- Round

- Zinc coated

- Rubber Pipe Cap

- Galvanized

ERW G.I.Pipe Trade Information

- Cash Advance (CA)

- 100 Ton Per Month

- 3-4 Days

- All India

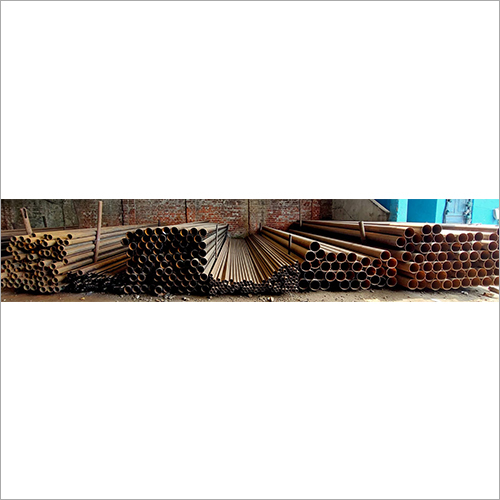

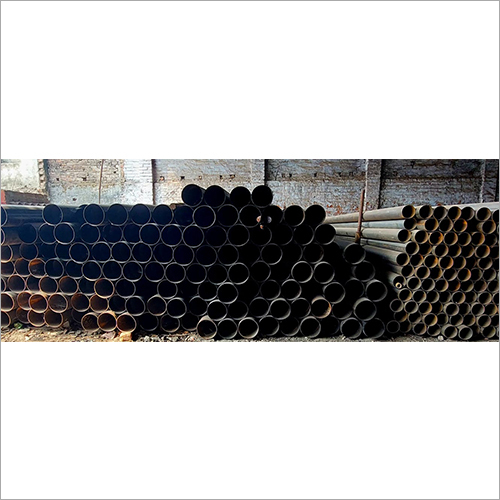

Product Description

We are a reputed company that is offering ERW G.I. pipe to our valuable customers. It is popularly known as electric resistance welded pipe galvanized pipe. It is primarily employed in various industrial and domestic applications. It is extensively employed in water supply systems for transporting portable water. ERW G.I. pipe is widely employed in plumbing systems for the conveyance of water, gas and other fluids. It is widely employed in irrigation systems for the transportation of water to fields and crops. It is also utilized in the automotive industry to manufacture exhaust pipes, roll cages and other components.

FAQs of ERW G.I.Pipe:

Q1: What is an ERW G.I. pipe?

A1: An ERW G.I. pipe is a kind of steel pipe that is fabricated using the electric resistance welding process. It is produced using galvanized iron or steel, which implies it has been covered with a layer of zinc to safeguard it from corrosion.

Q2: What is the reason for galvanizing G.I. pipes?

A2: Galvanizing G.I. pipes involves applying a protective zinc coating to the outer layer of the pipe. This coating provides corrosion resistance and expands the lifespan of the pipe. Galvanized pipes are regularly utilized for water distribution, plumbing, and in outside applications where openness to moisture and the components is a worry.

Q3: How are ERW G.I. pipes different from different kinds of pipes?

A3: ERW G.I. pipes are distinct from different kinds of pipes, for example, consistent pipes or welded pipes produced using different materials, in that they are made through the electric resistance welding process and are specifically covered with a layer of zinc for corrosion protection.

Q4: Are ERW G.I. pipes suitable for underground applications?

A4: Indeed, ERW G.I. pipes can be utilized for underground applications, yet they should be appropriately covered and safeguarded to forestall corrosion. Sufficient corrosion prevention measures, like using corrosion-resistant coatings and ensuring legitimate installation, are essential while using G.I. pipes underground.

Q5: How are ERW G.I. pipes installed?

A5: ERW G.I. pipes are typically installed using standard plumbing or pipeline installation techniques. This includes cutting, threading, and joining pipes using pipe fittings. Appropriate sealing and connections are essential to forestall releases and guarantee the integrity of the pipeline.

Q6: Are there any limitations or considerations while using ERW G.I. pipes?

A6: While ERW G.I. pipes enjoy many benefits, it's essential to consider factors like legitimate maintenance, potential for zinc coating degradation over the long haul, and the suitability of G.I. pipes for specific applications. At times, different materials like PVC or stainless steel might be liked. Additionally, the utilization of G.I. pipes in touch with certain chemicals or in high-temperature applications might require special consideration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+